Offering Quality Diamond Burnishing Tool You Need

Diamond Burnishing Tool

We are engaged in manufacturing and exporting a wide range of Diamond Burnishing Tool of burnishing tools that is used to finish heat treated jobs with hardness up to 65HRc.

Taper / Angle Burnishing Tool

Our vast range of Taper Roller Burnishing Tool These tools have widespread application in angle, taper, conical profiles where low surface finish is to be achieved.

Roller Burnishing Tools

We are Manufacturer, Exporter, Supplier and Trader of Roller Burnishing Tools. The roller burnishing tool is used for finishing of metal components after a pre-machining process.

Single Roller MSRT Burnishing Tool

We also offer a wide range of Single Roller MSRT Burnishing Tool Tool to our clients which is a versatile tool that can be used for multipurpose.

External Diameter Roller Burnishing Tool

We manufacture, supply and export a wide range of External Diameter Burnishing Tool to our clients for burnishing plain

Roller Burnishing Tools

The roller burnishing tool is used for finishing of metal components after a pre-machining process. This process gives a very low surface finish and a close dimensional tolerance.

Internal burnishing tool

Based on advance technology, we are involved in offering unmatchable quality of Long Internal Burnishing Tools. These Long Internal Burnishing Tools are known for their hassle free performance.

Mirror rolling cutter

101mm 105mm 108mm 110mm Mirror rolling cutter high effective inner hole roller burnishing tool through / blind hole rolling tool. burnishing tool through / blind hole rolling tool at Aliexpress for .

Inner hole roller burnishing tool

Shop mirror rolling cutter with fast delivery and free shipping. The side mirror rolling cutter is designed for vertical cutting, you can quickly get a good effect.

Roller Burnishing, While Overlooked

Based on advance technology, we are involved in offering unmatchable quality of Long Internal Burnishing Tools. These Long Internal Burnishing Tools are known for their hassle free performance.

Roller Burnishing Tools

With the constant support of our dexterous crew of technocrats, we are fulfilling the varied requirements of clients by manufacturing and supplying optimum quality of products

External Roller Burnishing Tool

We are one of the trusted names of the industry engaged in offering a superior quality range of External Roller Burnishing Tools to the customers. These products are manufactured at the vendors' end by utilizing the most modern facilities

Universal Burnishing Tools

The Cogsdill UBT-T series are designed for use in an indexable turning holder configuration, mounted to a machine turret on a lathe. Four basic styles are available in both left-hand and right-hand versions.

OD Carbide Roll Burnishing Tool

Operations while obtaining superior surface finish The OD Carbide Roll Burnishing Tool is designed to burnish outer diameters, tapers, radii, face surfaces, and internal bores

Black Carbide Roller Burnishing Tool

We are engaged in offering Industrial Roller Burnishing Tool to our clients. Our range of all products is widely appreciated by our clients

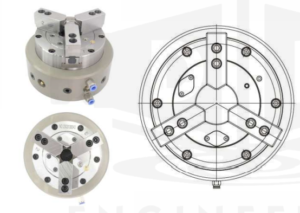

Jaw Type Pneumatic Chuck

Built in rotary cylinder, No draw tube required, No rotary cylinder required, Extra large piston, Provide high clamping force, Center through hole, Facility auto feeding, Solution for manual lathe into automation, No fluid direct to the chuck body,

Jaw Type Hydraulic Chuck

Built in rotary cylinder, No draw tube required, No rotary cylinder required, Extra large piston, Provide high clamping force, Center through hole, Facility auto feeding, Solution for manual lathe into automation, No fluid direct to the chuck body,

Jaw Pad for Rotary Power Chuck

JATO Rotary Power Chuck also has quick-change jaw/collet design, helping you to cope with parts of various dimensions.

Rotary Power Chuck with Head

Built in rotary cylinder, No draw tube required. No rotary cylinder required. Extra large piston. Provide high clamping force. Center through hole. It able to arrange auto feeding. Best budget solution for manual lathe into automation. No fluid direct to the chuck body

3-Jaw Pneumatic Chuck

Pneumatic power chucks from the perfect alternative if the chuck is not to be actuated manually or via hydraulics. The chucks have an integrated pneumatic cylinder, via which the chuck can be actuated in the event of a shutdown.

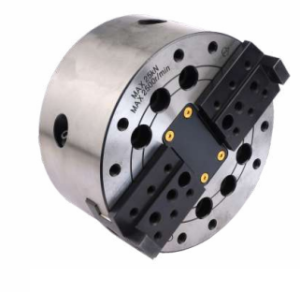

2-Jaw Power Chuck

2.Jaw long stroke power chucks gripping typical unconventional formation components. It can be operated using standard stroke hydraulic cylinder. Power operated hollow high speed chuck. High rigidity and high repeatability precision. Deliver up to 20% more speed, gripping force, and bore size when compared to conventional chucks,

Vmc Stationary Front-Mounted Pneumatic Chuck

Stainless Steel Chuck Body. Dead length design no axial movement. Cost effective stationary collet chuck. High resistant to chips, fluid and dust. High rigidity. Long product life

CNC Machine Collet Chuck

CNC machine collet chucks are essential tools in the precision machining industry, providing the necessary grip and accuracy required for various CNC machining processes.

CNC Machine Spindle Cartridge

The components of spindle are Hardened & Ground to be obtain High Precision and long life. High accuracy bearings class P.. -4 are used for angular contact match paired.

VMC Machine Spindle Cartridge

Belt-driven spindles are a popular choice and make up a large percentage of spindles. Specially designed with belt driven, the accuracy of spindle nose is strictly under 0.007mm. Spindle unit allows to perform all types of machining applications such as drilling, tapping, milling, boring, facing, reaming and countersinking.

Roller Burnishing Tools

The surface of metal parts worked through turning, reaming or boring operations is a succession of "PROJECTION or PEAKS" and "INDENTATION or VALLEY" when microscopically examined (see fig. 1). The roller Burnishing Operation compresses the "Projection (Peaks)' into the "Indentation" (Valleys) thus forming a smooth mirror finished surface (as in fig. 2). Any material not exceeding 40 Rockwell Hardness "C" can be rolled bumished

Multi Head Spindle

We make multi Head Spindle for the purpose of more than one hole at single operation at different P.C.D. as per your requirements with grease or oil. Which can be widely used to drill products like printed Circuit Boards : Engine heads and other Automobile components- Extreme care should be there to drill multi holes at different layouts- It helps to achieve accurate and identical drilled layouts in mass production

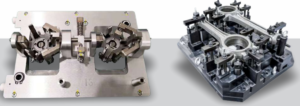

Jig and Fixture

A jig's primary purpose is to provide repeatability, accuracy, and interchange ability in the manufacturing of products. A jig is often confused with a fixture. A fixture holds the work in a fixed location.

Hydraulic Chuck

power chuck rotates at high speed, Suitable for modern turning center. These power chuck have a large through bore and are suitable for bar work compact in design and less weight.

Collet Chuck

Collet Chuck is available in three size 25, 42 and 60. These Chuck are interchangeable with power chuck. Collet chuck type has spring collect type collect chuck with great rigidity and infallible. Collect Chuck increase efficiency and productivity always high performance, cost effective and great stability.

Stationery Chuck

Stationery Chuck for self centering clamping on milling machine, Drilling Machine & Special Machine. The Compact Construction of these chuck provide maximum working space, these chuck with a in built cylinder can be operated pneumatically or hydraulically with a flexibility of using a vertically positions.

UBL Chuck

Universal Ball Lock Chuck ensure clamping of components & face butting. The UBL Chuck is a locking type power chuck that offers high levels of gripping performance, rigidity and durability to allow secure gripping of cast or forged materials with a draft angle and workpieces with an overhang, which conventional chucks can not grip. Also, they can improve the roundness of thin-walled

Pulldown Chuck

These chucks are designed with performance of pulling clamp. Pull-Down type chuck (PA Type) is inside clamping chuck with completely pulling performance by chucking pins.Chucking pins locating at 3 position can reduce bending stress of clamping the work-piece each other. So, These chucks are designed with high accuracy of concentricity and strong clamping performance.

Pneumatic Rotary Chuck

VMT pneumatic rotary chuck is built in cylinder & compact in design. Suitable for light work compatible to hard & soft jaws. Can be installed on rotary table for indexing machining Sealed against dust & cutting chips Case hardened body to assure long chuck life.

Compensation Chuck

Compensation Chuck has spring loaded center point that locate the part against a chuck mounted part rest & either two or three jaws that are connected as a swivel internal to the chuck so that they can clamp on a surface that is not concentric to the locating center.

6 Jaws Chuck

Jaws chuck offer the ability to hold thin wall parts with minimal distortion. This result in minimal distortion to the machined area. If you are machine an internal diameter it will remain round after it is unclamped.

Four Jaws - Two Motion Chuck

Four Jaws - Two motion chuck, where two jaws are self-centering and two jaws are independent. These chuck is suitable for block and non uniform shapes.

Expended Mandrels

xpending mandral collet chuck is use to the ID of part in which high accuracy and torque transmission due to fixed out mandrel. it is used in turning, milling and granding machine.

Revolving Center

high Speed Revolving Center. Revolving Center are typically used for supporting long work piece rotating at high speed.

Face Driver

ace drive to improve productivity & quality have led to the need for faster machining technique. Face drive along with today new high performance equipment led you maximize your production capability for minimal.

Tail Stock

ail stock for VMC machine. It is usually used to apply support to the longitudinal rotary axis of a work piece being machined. Tail stock is mounted on machine bed, and inserted against the sides of a hole in the centre of the work piece.

Rubber Collet

Rubber grip collet for push type or draw type collet chucks. Full griping area: high rigidity, more gripping force. Gripping smoothly: prevent to damage the work piece. More accurate than standard spring collets.